Look who’s talking

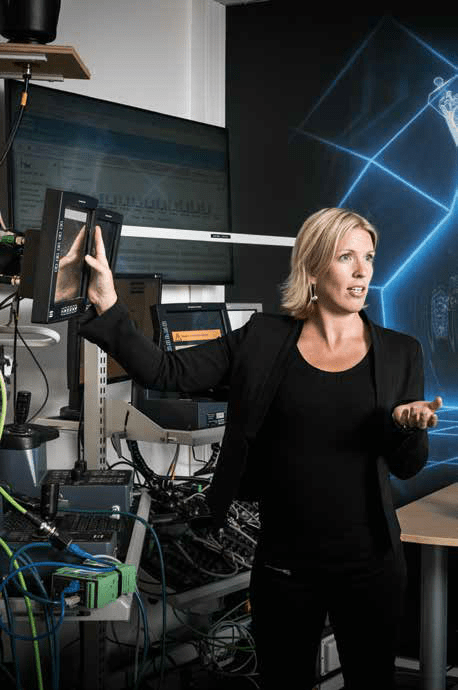

Karin Jirstrand switches on her Pit Viper drill rig and starts the engine ? but rather than tramming off in the machine, she logs into a web portal.

“You can follow what the machine is doing here,” she says. “Right now I?m going to run through a drilling process to verify that everything can be seen in the portal.”

We?re not in a mine somewhere. Instead we are at Atlas Copco?s automation department in Örebro, Sweden, where Karin Jirstrand is the project leader in a team that is working to connect digitally to all machines. The control panel she is sitting at is identical to that of the Pit Viper drill rig, but in all other respects the panel is a virtual one. Just like more than 700 operating Atlas Copco machines around the world, it is connected through the Certiq telematics platform. All the machines can be tracked via the web portal, and now Karin tests various alarms on her control panel to check that they can be seen there.

She then looks at her laptop on the Certiq portal to track two real machines.

“They have had an abnormally high number of alarms over the past 24 hours,” she explains. “One of them has stabilized, so the operator must have remedied the fault. The other one is still having problems, so I need to download the settings and assess them.”

Karin Jirstrand Product Manager Interoperability, Atlas Copco

AT THE LAB in Örebro, Karin and her colleagues are coming up with definitions to allow the easy evaluation and tracking of more than 60 different models. Their work helps the Atlas Copco Customer Centers around the world to become more proactive and the equipment to be used more efficiently. Atlas Copco?s goal is for the majority of machines to be connected by 2020. New products are being designed in order to achieve this, while older machines are being adapted so that they can be linked through Certiq. The idea is to collect as much valuable information as possible, which can then enable customers to use their equipment to its full potential.

“We need to ensure that customers are getting the most from what they buy.” Olav Kvist Vice President Mining Technology, Atlas Copco

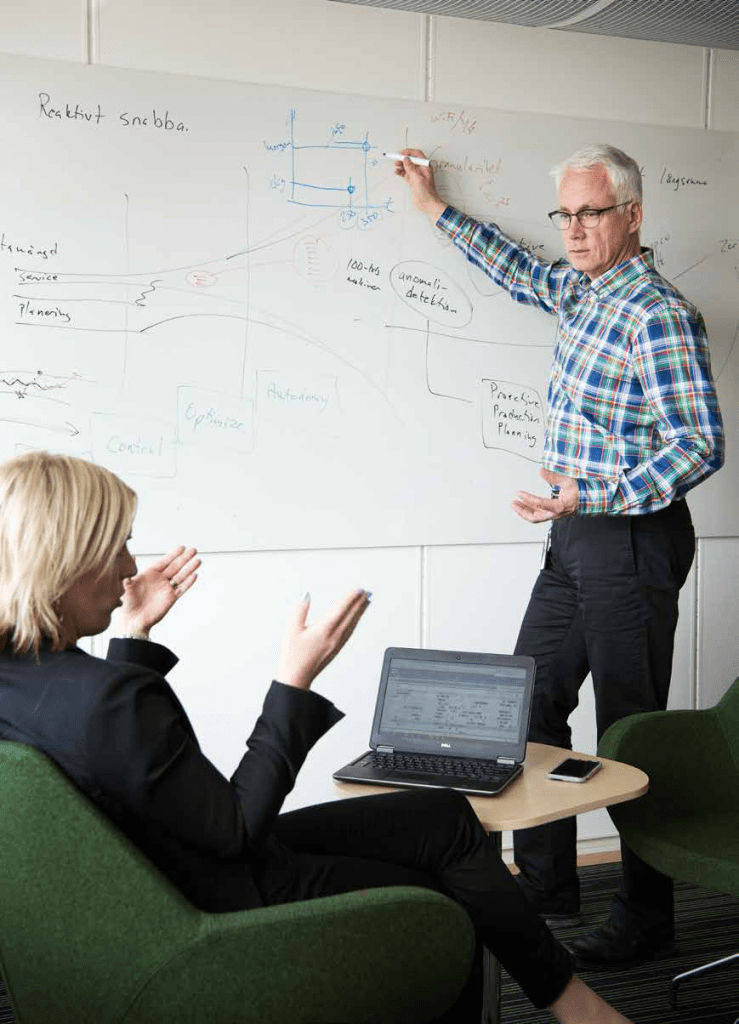

“Atlas Copco?s job is not just to develop and sell good equipment and then provide quick service. We also need to ensure that customers are getting the most from what they buy. We are moving from being quickly reactive to being slowly proactive,” says Olav Kvist, Vice President Mining Technology.

He continues:

“Take spare parts, for example. Traditionally, our role was to supply new parts as quickly as possible when something broke down, but if you can measure the ?health? of a machine then you can predict when the part is going to fail. We call it anomaly detection. It means we can send spares efficiently and in an environmentally friendly way, replacing a part before its failure causes the machine to stop working. Our vision is to have zero unplanned stops, since the cost of having expensive machines standing still is high.”

EXTRACTING DATA FROM equipment is nothing new to Atlas Copco, but the methods and possibilities have changed radically. In the 1990s various types of portable memory were used, moving in the early 2000s to satellite communication in the ProCom system. Now it is done by wireless telecommunication, so at the heart of Atlas Copco?s work is Certiq ? a telematics solution that is available for all types of mining and construction equipment, both surface and underground. Real time data allows owners and operators to monitor and optimize the operation of their equipment at any time and from anywhere.

Olav Kvist pulls out his laptop and logs on to the Certiq portal. One customer page displays a chart featuring low yellow and green bars, and considerably higher red ones.

“Red means that the machine has been shut down, yellow that it is idle and green means that it is in active production. It shows this data for each 24-hour period and as you can see in this example, the machine is operating at a low rate. That is the reality for most of our customers, and we want to help them increase their productivity.”

Karin Jirstrand nods and interjects:

“It?s about generating business benefit from the opportunities offered by the Internet of Things and the Industrial Internet. For our part, it is about helping customers to connect digitally with their fleet ? but also to interpret the information provided by relevant indicators. Partly so that we know when preventive maintenance is needed, and partly so that our customers can create optimal strategies for achieving their business goals.”

ATLAS COPCO HAS around 64 equipment models connected, which creates a major challenge when creating useful indicators and benchmarks ? they need to be relevant to each customer in each given context.

“We want to make data available to other contractors or third parties selected by our customers.”

“Demand for benchmarking figures has increased enormously,” says Olav Kvist. “Our customers want to know what good looks like. It?s only once they see relevant information from a comparable part of the world that they know how they are doing, so we are giving benchmarking high priority.”

He continues:

“Sales are of course important, but the most important task for us is to help the customer increase their productivity. Certiq will give our product managers the ability to identify customers that might need help in taking the next step when it comes to productivity. Quite simply, we want to take greater responsibility for the customer?s business. Our aim is that our customers will do better than comparable companies. I have been a product manager myself, and I know the great difference between theoretical performance and real productivity. While theoretical performance can be dismissed as sales talk, the information available in Certiq is on a completely different level. What you can see in Certiq shows the reality in black and white.”

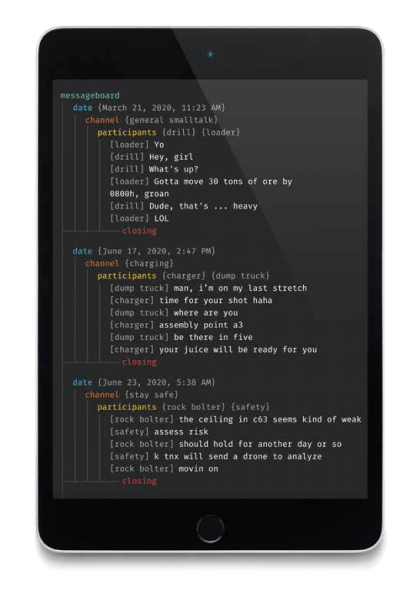

TO GENERATE THE MAXIMUM possible customer benefit, Atlas Copco is also facing a number of technical and practical challenges outside of the actual telematics solution ? such as connectivity underground or for remote areas, having the data secured from non-trusted sources and available to trusted ones.

“We need to create interfaces so that all our information works with other systems that the customer is using, like Maximo for maintenance or the Dassault system for dispatching, just to name a few,” says Karin Jirstrand. “Generally speaking, we are in favor of open access. We want to make data available to other contractors or third parties selected by our customers so that they can utilize data to create services that maybe we haven?t thought of. The more people who can benefit from the data, the more it increases the value of our equipment. It?s a winwin situation.”

SO ALTHOUGH THERE are lots of challenges, the opportunities are many more and much greater. When 5G becomes standard, remote services will be taken to a whole new level. For example, it will be much easier to troubleshoot and update programs remotely ? which will lead to an explosion in the market for connected equipment.

“We are firm believers in the value of information from our connected machines,” says Karin Jirstrand. “They carry a huge amount of data that needs to be interpreted and converted into usable information. By using this to make comparisons, we can help our customers become more efficient.

The future looks extremely exciting!”

Q&A Martin Wallman, Product Manager, Customer Center USA

The automation department in Örebro, Sweden, makes sure that Certiq, Atlas Copco?s telematics platform, can be of optimal use to customers.

In early 2016, the first drill rig was connected through the Certiq telematics solution in the US market. Since then more than a hundred machines have been connected, with new being added every week.

Q How has Certiq been received in the US?

A “The response from our customers has been very positive. Maintenance people are using the planning and service part to optimize their service operation, while people that are more focused on the operational side of the business are primarily using the machine performance data available in Certiq to fully utilize the machine. In the end, Certiq is a tool to help our customers to reduce their total cost of ownership and optimize their operation.”

Q What are the main challenges for the customers to use Certiq to the max?

A “It is important that the customers understand how the data is collected and what it is based upon when they are looking at different KPIs in the Certiq portal. What is key to one customer might not be as important to another. Therefore, we give our customers the possibility to modify and adjust what they can see in the portal to what will fit them best, based on their operation. Connectivity was something that our customers had some initial concerns about, but so far we haven?t seen any need for a satellite connection, which is an alternative to the standard 3G solution for surface customers. Going underground, a local network is required if pickup points are not the preferred solution.”

Q How has Certiq changed the way you work within the parts and service field?

A “It enables us to be more proactive and efficient. We can support our customers in a more proactive way since we know how the machine fleet is utilized, or for example when a specific machine is due for service or is having operational issues. This will of course reduce and minimize customer downtime while also lowering the total cost of ownership. As more machines get connected, and we produce more KPIs, we will also be able to reach out to customers to discuss how we can help them improve their profitability and not just performance and service.”

Steve Molter Rental Equipment Manager, Luck Stone

How is your fleet connected to Certiq

What kind of machines, and how many, do you have connected through the Certiq telematics solution?

“We have two SmartROC D60 drill rigs connected. Luck Stone is a mining operation based in Richmond, Virginia. We are one of the largest family owned and operated producers of crushed stone, sand and gravel in the US, and we use those rigs every day.”

How has Certiq changed the way you use your machines and operate your business?

“It has helped us to better utilize and monitor our production. Before, we relied on the drillers to provide us with information using pen and paper, but with Certiq we are a bit more accurate. The machine performance data enables us to maximize how the rigs are operated, be it drilling or tramming. We are also able to track and monitor our moving from location to location. I would also like to mention that the CO2 monitoring system in Certiq has been very beneficial. It has helped us track our emissions, which is a big benefit for our environmental stewardship program with the State of Virginia.”

What has been the gain for the company?

“Using the SmartROC D60 drill rigs more efficiently, Luck Stone has improved production by at least 8?10 percent. We are very happy with Certiq and the information that can be extracted. With time, we learn more and more about the system and I am certain it will help us be even more efficient in the future.”

Epiroc operated under the trademark “Atlas Copco” prior to January 1, 2018.

Here:

Us: